Structural Steel Repair 2025

At Alpha Mar Group, we recently completed a challenging ship repair and steel replacement project in Houston. The work demanded precision, teamwork, and a serious learning curve — and our team rose to the occasion. Our highly trained and skilled employees came together, exceeded expectations, and completed the repair safely and without mistakes. The job was fully accepted by Class and the U.S. Coast Guard, showcasing our commitment to quality and technological advancement. Proud of our dedicated personnel and proud to continue leading ship repair in the Gulf Coast.

Shell Plate Repair 2024

Steering Gear Repair 2024

Propeller Hub Cap Repair 2024

Jack Up Rigs Leg Operation 2023

Anchor Chain Replacement 2022

Hopper Fabrication 2022

Alpha Mar was contracted to fabricate a custom hopper for a private terminal. The hopper was entirely designed and engineered from scratch, then fabricated and tested by AMG. AMG’s hopper is a one-of-a-kind hopper, designed with the unique attribute to carry a wide range of bulk products from fertilizer to metal ores to crushed concrete.

Hydraulic Cylinder Rudder Engine 2021

Hoisting Wire Gear Box Exchange 2020

Bow Thurster Installation 2020

Free Fall Boat Davit Repair in Miami 2019

Our client’s vessel suffered a stern damage which also affected the free fall boat davit. Due to the critical importance of the davit, repair couldn’t wait until next dry dock and the vessel had to keep delivering containers to the Caribbean Islands. We decided to remove the davit, repair it on spot and mounted it back once the vessel returned to Miami.

Crane Jib Repair / Installation 2019

Crane Foot Bearing Removal 2018

Port Of Houston Barbours Cut Terminal 2018

In preparation of the hurricane season Tie down and Stowage pockets were installed by the Alpha Mar team in order to secure the container cranes at the Port of Houston Barbours Cut Terminal. The completion date was especially critical here and so two shifts were worked in order to fulfill the customer's requests, showcasing our adaptability and duty to the customer.

Hatch Cover Repair 2018

One of the operating arms of the hold no. 1 hatch covers got bent and the hinge broke. We fabricated a complete new box including sleeve and pin. The old box was cropped out and we fabricated a new box which was fitted, aligned and welded. The job went on in 2 shifts and the vessel could sail to its next destination.

Wire sheave repair 2018

Portable Crane 2017

Alpha Mar was recently contracted by Enterprise Products to custom build a 1-ton Portable Jib Crane for their terminal operations.

The crane is one of a kind with Marine grade Aluminum construction for ease of movement due to its lightweight. The added stabilizers on the base of the crane can be used to lift the crane during operation to ensure that the crane does not move. The design, construction and testing were all done right here at Alphamar and is a testament to our company’s teamwork and strict adherence to our client’s needs.

Gangway extension 2017

MacGregor crane hook repair 2017

Maersk Drill Rig Pipe Installation 2017

Port of Houston Bulkhead Sand Blasting and Coating 2016

Alpha Mar successfully bid and got awarded the Port of Houston 2016 Splash Zone Painting and Associated Bulkhead Repairs at Woodhouse Terminal. Project consist of sandblasting, cleaning and coating the splash zone of more than 1,800 linear feet of bulkhead under wharf 1, 2 and 3 at Woodhouse terminal. Project was completed on time, under budget while meeting and surpassing all client's specs and inspections.

Maersk Drillship Cabin Refurbishment 2016

After one of the cabins on Maersk Drillship burned up due to a faulty computer charger, Alpha Mar Group was assigned to refurbish / recondition this cabin while the ship was still at sea. Pre-fabrication of furniture was performed as per clients standards and installation went through in less than a week, making this a successful on time, on budget project for both the client and Alpha Mar Group. (Picture shows cabin condition at 85% finish)

Main engine inspection 2016

Telescopic Gangway Repair 2016

Side Shell Repair Care Terminal 2016

Heating Coil + Shell Plate Repair Houston Anchorage 2016

A lot of logistics and labor were involved in order to finish this job on time. 2 launch boats were travelling between Galveston and the vessel daily. The cargo tanks had to be cleaned and the heating lines to be pressure tested and repaired. Our highly qualified plumbers were able to replace and solder the special AL BR pipes and fittings. Another damage on the vessel's shell plate was also repaired during this time.

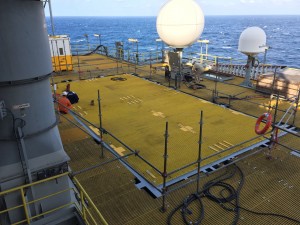

Maersk Semi Submersible Rig -Drop IN Platforms 2016

After removal of their secondary ROV, Maersk Offshore Semi Submersible Rig needed to find a way to cover the area with out losing the possibility to re install a secondary ROV on Board. Alpha Mar Engineers design and fabricate 4 Drop In Removable Platforms which gave the rig extra space having almost same structural capacity as existing deck with out losing future modification opportunities. Fabrication was perform in our structural steel shop minimizing end user cost with out compromising precise fit up.

Container Vessel HFO Tank Damage 2016

Alpha Mar Group responded to inspect a crack on the vessel's side shell plating. During the inspection inside the HFO tank some buckled and cracked web frames were discovered too. On the same day we deployed a cleaning team and equipment to the vessel and started with the repairs. Our quick response time has again been proven to be the way to success.

Painting hull of a tanker 2015

If you know how, the Port of Houston allows you to paint your vessel's hull. Here we just finished the complete PS of one tanker at City Docks with more than 32% power brushing, 2 coats of primer, one full coat of paint and repainting the logo. The job was carried out around the clock and due to favorable weather the complete job was finished within 2 days.

Maersk Drillship-Completion Bridges 2014/2015

Maersk Offshore Drill Ship required more space during their "completion stage" For which Alpha Mar - IMW Team Fabricated and install 2 - 25 Tons Completion Bridges to be fitted between BOP Gantry Crane Rails. High Tech Laser Measurements where taken by Alpha Mar - IMW Team to guarantee fitment. CNC Plate cutting was utilized 100% to ensure precision fabrication.

Maersk Drillship – Filterpress Piping 2015

Maersk Drillship needed to install two new filters on their pipe deck which required approximately 2,000 linear ft of new piping going from port's mud pump room all the way to starboard on the pipe deck. Alpha Mar-IMW team went on board to perform this work while the vessel remain under standard drilling operations. Project was done as a design and built with critical delivery schedule. Some bulkhead penetrations had to be done to pass the pipe from one room to another, which was no big challenge for Alpha Mar-IMW having already work many times with different classification society fabrication codes. After job completion, job was inspected by ABS surveyors with excellent remarks from their part.

Propeller Straightening 2014

There are not many companies in the market who are able to straighten propeller blades. We were requested to straighten 2 propeller blades while the vessel was afloat under supervision of the class. With experience and know-how we straightened the 2 blades to save the owners an expensive dry docking and reduced the vessel's down time to a minimum.

Rudder stock repair on a laden vessel 2014

A chemical tanker hit the berth while leaving Houston after loading and damaged her rudder stock from the pintle rudder. The vessel was not allowed to discharge the same cargo in the States. We removed the rudder and stock in laden condition. The rudder stock was straightened and the rudder carrier and foundation machined.

Generator Rewinding 2021

Hydrophore Tank Fabrication 2020

Wire Sheave Repair 400mt 2019

Ultrasonic Hatch Cover Inspection 2019

Sludge Pump Installation 2019

Stern Damage Repair 2018

A tanker had a collision which caused extensive damage to its Aft deck plate and side shell plate. The panama chocks along with the angle stiffeners were also damaged. Alpha Mar began by cropping out the plates and the panama chocks. The damaged sections of the angles were also cropped out. New AH/DH36 plates were welded and new panama chocks were fitted onto the aft deck plate. The housing box for the emergency towing rope was also found to be damaged. It was renewed with new angle supports and hinges and welded back in place.

NMF Crane foot bearing repair 2018

With a growing age of many fleets, the need to carry out extensive repairs during port stays increased. Here we carry out the exchange of 2 crane foot bearings together with our partners HMB Lintec from Buxtehude. The job was done within the anticipated time frame to the satisfaction of all involved parties.

Hatch cover repair 2018

Crane foot bearing exchage 2018

Stainless Steel S Bend Reducers 2017

Alpha Mar Gangway 2017

Shell plate insert tanker 2016

Launch boat reapir 2016

Maersk Drillship Potable Water Pipeline 2016

Alpha Mar Group was challenged to change all the existing carbon steel potable water pipeline of one of their clients drill ship to a less corrosive material, in the most affordable and fastest way possible, while minimizing downtime. Alpha Mar suggested the use of press fitted stainless steel which help to complete demolition and installation of more than 1,200 linear ft of 3" and 2" pipe in less than 2 weeks. Project exceeded client's expectations and is planned to be repeated on their sister ship.

75 mt double bit bollards 2016

Hatch Cover Hydraulic Cylinder Repair 2016

Over the weekend we carried out a repair of a hydralic cylinder for the hatch covers on a BBC vessel. We removed the cylinder, openend it, repaired damages to the liner and mounted it back together with new seals. After pressure testing we delivered it back on board. Reliable and quality service around the clock.

Sewage Treatmant Tank Fabrication 2016

One of our good clients was in need of a new sewage treatment tank. A new tank from the maker was obsolete and they asked us if we will be able to fabricate a new one for them. Our engineers went on board to gather necessary information and measurements needed for the new fabrication of the tank. One week later the tank was ready for shipment.

Heating Coil Repair Off Galveston 2016

The word spreads. Alpha Mar is specialized in heating coil repairs. Our experience and vast knowledge of working with different kind of pipe materials enables us to finish all kind of heating coil repairs even while the vessel is far away from the shore line. Although work orders changed our team kept on working focussed and dedicated to complete this job to the vessel's managers satisfaction.

Shaft Generator Repair 2016

Our engineers flew to Kingston / Jamaica in order to carry out troubleshooting and repairs on a shaft generator. Unfortunately they discovered severe damages which could not be repaired on board. The German owner than flew the generator to Houston where the generator shaft was welded and machined as well as other repairs carried out. A couple of days later the generator left our shop fully overhauled and tested.

Cargo Hold Cleaning 2016

Maersk Drillship IWOCS 2015

Maersk Offshore Drill Ship needed a way to load their FMC IWOCS equipment directly from their ship to the ocean floor. Alpha Mar - IMW Team fabricated and installed 3 pedestals and 2 cantilever beams on board.The 3 pedestals hold the winches and the FMC equipment required for the lowering of the IWOCS . The 2 cantilever beams above the moon pool carried the load of the equipment, lowering and data wiring. Project was done as a design and built with a tight schedule under vessels normal completion operations.